There are constant changes in the T&C as this is an industry with heavy international competition, requiring continuous improvements.

Key innovations for the T&C industry, according to the EURATEX report, can be found in the areas of:

- Smart high-performance materials and products;

- Digital manufacturing and supply chains;

- Bio-based materials & processing.

Furthermore, it is stated that the Smart Textiles area (electronic textiles and smart wearables) is booming. The EU smart textiles market is expected to reach € 1.5 billion in 2025!

It is clear that digital evolution will play a great role in the T&C industry’s further developments. In the near future, the IoT (Internet of Things) revolution will totally change how the production machines operate while gathering data on all processes will cement big data in the decision-making at all levels. At the same time, the design within the fashion manufacturing and within the technical textiles sector moves to a completely digital process, allowing fast simulation of the created products to evaluate their effectiveness before they are actually produced.

The future for textile graduates is bright and digital, and they need to be trained to be able to handle the several changes that are expected in the coming decennium.

Simulation-based engineering, nowadays go very far, in all levels of the textile industry. First, there are polymers used for man-made fibers. Molecular modeling allows the optimization of polymers for specific needs and accelerates the development of new bio-degradable fibers.

The second level is the fibers. Here there are advancements in fiber testing, with automated tests, and lab management systems. Fibers for specific conditions can be selected making use of neural networks, while all historical information is stored in databases, allowing for the use of big data techniques. Fibers properties themselves are modeled to fully understand their reaction to external stimuli.

The third level is the yarn. Several new fancy yarns appeared on the market allowing new applications.

From the yarn, or from fibers, the fourth level, fabrics, and textile assemblies, are made. ICT is used for all aspects of fabrics: in the design and for the simulation of the behaviour, for the calculation and the transfer of machine settings, in the development of complex 2D and 3D structures, and for the integration of complex parts such as heaters and sensors.

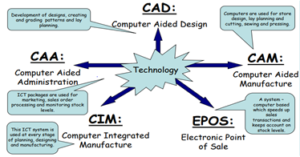

CAD/CAM (computer-aided design and computer-aided manufacturing) are computer software used for design and manufacture prototypes, finished products, and automated production management. Apart from modeling, several new production technologies broke through since 2000, requiring complex tools for their designs and to guide the production machines. We can mention for example 3D weaving, smart textiles, electrospinning, embroidery technology, 3D printing, 3D body scanner for clothing production, 3d knitwear.

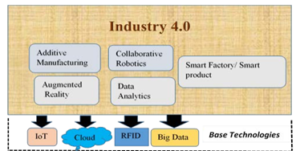

Figure 1. Industry 4.0 framework with base technologies

ICT systems are also used for quality control, production, operational and human resources management, and administrative procedures.

A schematic representation shows the 5 main examples of computer systems used in the Textile and Clothing Industry:

Figure 2. The main examples of computers systems used in T&C industry

If the developments and the benefits associated with the ICT systems applications to the textile and clothing sector are considerable, a barrier to a better digitalisation of the industry is represented by the shortage of skilled personnel.

This is what emerged from recent research conducted during 2020, in the framework of the European project ICT-TEX “ICT in textile and clothing higher education and business” aimed at detecting the most required technological and ICT skills from the T&C businesses.

The questionnaire was addressed to people covering managerial positions in companies having different kinds of specialties.

The main results that emerged from the survey were:

- Most of the companies interviewed use automatic programs, even if the production stages are mainly managed by the personnel, this means that there are still large benefits to be obtained by better embedding automated systems in the production process.

- Innovation is considered an important aspect by the T&C companies, who indeed require from their employees the ability to improve the production lines and to develop new kinds of products. On the other hand, they believe that these kinds of competences, together with those related to technological and ICT skills are the ones that the technical staff need to improve the most.

- The ability to manage pieces of machinery exploiting the possibilities offered by their latest functionalities is among the competences most required as well, so covering also all the functions based on software, representing nowadays machineries essential components.

- Among the skills companies working in the smart textile sector need the most, there is the ability to develop new smart products, including also those skills connected to sensors and ICT components development.

- Finishing printing and functionalisation specialised companies have a low propensity for the adoption of innovative technologies. The main constraints in their introduction are probably due to the initial investments but also to the lack of specialized professionals able to properly operate with them. Indeed, we can see that among the skills most needed by these kinds of companies, we find technical abilities and special knowledge mainly related to specific dyeing and printing processes, as for example rotary screen printing technology, raster printing, colorimetric, and so on.

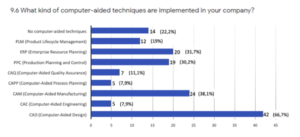

Concerning the implementation of computer-aided techniques among the T&C companies, we understand from the answers collected, that the most used is surely the Cad systems with 66,7% of usage. Moreover, Cam Systems is used by a good percentage 38,1%, then we have ERP with a percentage of 31,7% and PPC with 30,2%.

However, a significant figure is represented by the high percentage of companies that do not use any computerized systems, about 22,2% of the total.

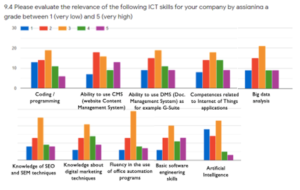

Furthermore, in reference to transversal ICT skills, we can note that the skills companies believe their employees need to improve mostly are the knowledge about social media / digital marketing instruments and basic software engineering skills, followed by big data analysis and the use of CMS and office automation programs.

It is clear that in order to let a better integration of ICT technologies into the T&C businesses, it is important to invest in human resources skills improvement, ameliorating and widening the offer of high-quality specialised training programs.

That is the main objective of the ICT-TEX project, which will develop at least 7 validated Study programmes (syllabuses) for technical, digital, and entrepreneurial education complying with the latest company requirements. The course developed will be freely available, modular, entirely practical, interactive, and suitable for distance learning, which is an advantage for people already working.

Silvana Laudoni, Project Manager at CIAPE, the Italian Center for Permanent Learning

Bibliography

- Euratex Annual Report 2018, https://euratex.eu/wp-content/uploads/2019/05/Euratex-annual-report-2018-LR.pdf

- Eurostat, News release 147/2020 – 5 October 2020

- Iyke, S., Tenebe, O.G, Yibowei, M., Akindiya, I., The evolving role of ICT in Textile Manufacture, In: Association of Textile Technologist of Nigeria 1st International Conference/AGM, Eko, 2012

- http://www.textile-platform.eu/

- https://designforlongevity.com/articles/the-evolution-of-the-fashion-industry

- https://www.aitex.es/smart-textiles-ict-solutions/?lang=en

- Tsiupka, I., Mason, A., The role of ICT in optimizing reverse textile supply chains, Master Thesis, 2015

- JuliiaTsiupka, Alicia Mason: The role of ICT in optimizing reverse textile supply chains, Master thesis- Textile management; 2015. The Swedish school of textile, University of Boras, Sweden.

- http://penyrheol-comp.net/technology/wp-content/uploads/sites/2/2014/06/computers-in-textile-industry.pdf